The Way We Work

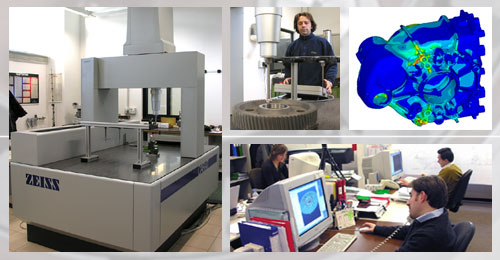

Cobra carries out its activity in a 10.257 square meter facility, using a range of up-to-date management techniques and tools. Complete design service of custom gearboxes is provided – in close collaboration with the customers - through a team of experienced designers equipped with modern CAD tools.

All of the operations are controlled through a computerized Material Requirements Planning (MRP) system. Specific manufacturing tasks (such as foundry, machining of gearbox cases, turning, gear cutting, grinding, heat treatments), as well as standard components are outsourced from a network of certified suppliers. All production parts and components undergo a very strict inspection process before being used for production. The mechanical assembly of gearboxes is carried out in-house by highly skilled professionals.

At the end of the assembly process, every single gearbox undergoes a very strict in-house bench test. Availability of spare parts for all Cobra products is guaranteed for 10 years. Services offered to customers include repair and reconditioning of gearboxes, and training for customers’ employees.